Back to Contents

Back to DCC

Link to Sitemap

Locomotive decoders for DCC

On this page we've put all the information pertinent to DCC locomotive decoders. We start with a our quick guide to fitting a DCC decoder, further down the page you'll find our decoder recommendations and at the bottom there are links to a couple of pages of more in-depth reviews of our current favourites. We've also done a quick guide to decoder CV programming

Decoder installation

So you’ve got your nice, shiny, new (etc.) control system home and even managed to blagg a couple of decoders so what now? Well, I'd grab the manuals for the control system and the decoders and have a quick browse. Then you can have a go at fitting one of the decoders; it's a good place to start. Make sure you've got the manuals to hand as the writers of the manuals will know best how to operate their particular equipment; here are some supplemental notes explaining our routine for decoder fitting, with the example of a Brawa BR232:

- Run-in the loco on analogue control. With r-t-r locos that probably means half an hour to an hour in each direction at mid speed. I use a rolling-road, Dave uses a circle of trainset track. If all is well move on to the next stage.

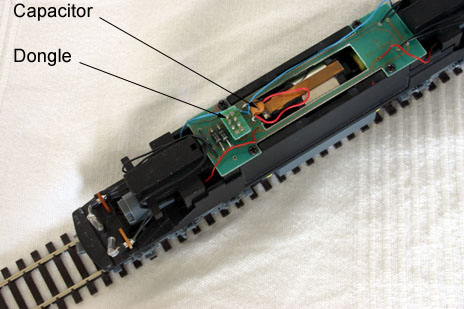

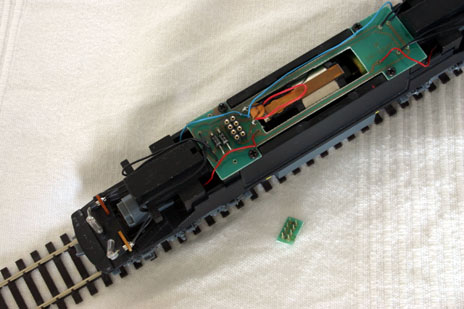

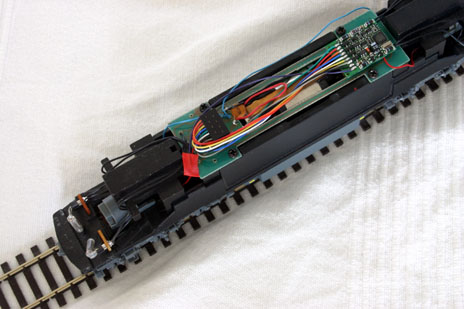

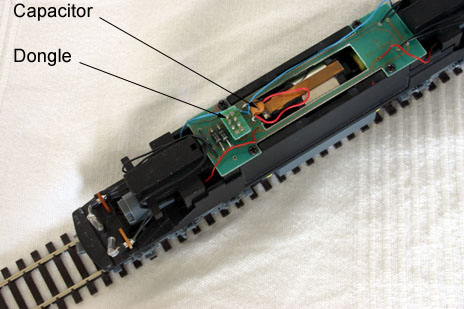

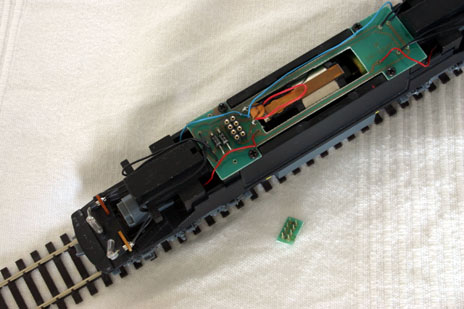

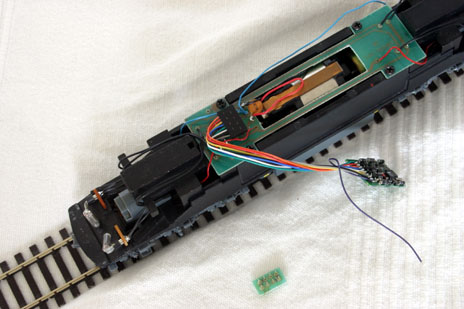

- Remove the loco body and check the circuit board. Identify Pin 1 which is normally marked with a dot, an asterisk or numeral ‘1’. Remove the dongle from the socket on the circuit board. If you can’t identify Pin 1 don’t worry too much! The Brawa 232 used as an example doesn't have Pin 1 marked. I tend to remove any capacitor that’s across the motor – it’s there for spark suppression to prevent the model causing interference when under analogue control. As most DCC decoders have the suppression function on board the capacitor is largely superfluous and it can cause erratic running. In this case I've left it in as the example loco hasn't been run-in yet...

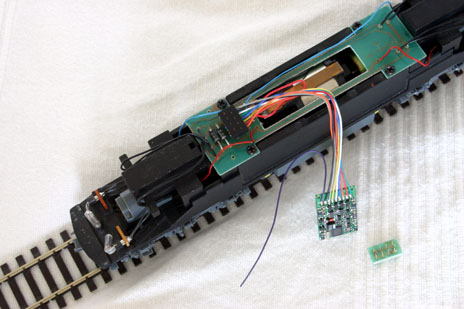

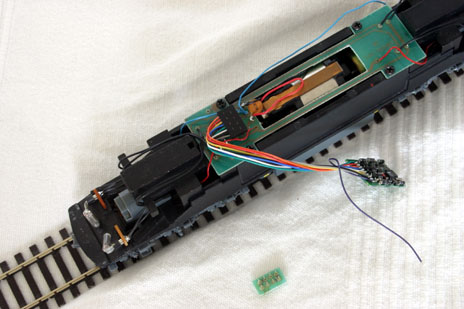

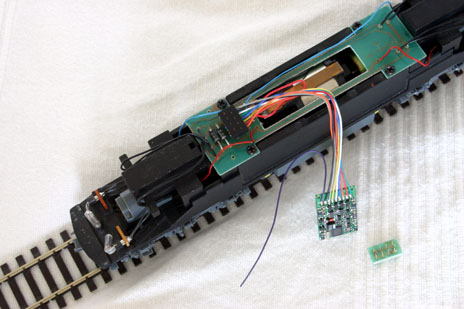

- Plug in your decoder – orange wire to Pin 1. The decoder in this example is a Lenz 'Silver', which supports one more function than there's space for on the plug. The ninth, purple wire is therefore free from the connector.

- Put the loco on the ‘Programming track’ and read CV1, the loco’s Address, this should return value ‘3’. You’ll need to look at your programmer/controller’s instructions to see exactly how to do this.

- If CV1 has been read correctly then you can put the loco on the Operating track and make sure it drives in the right direction and that the headlights go on and off correctly (the button on your control system may be marked Function 0, f0 or with a lights symbol). If the loco moves in the wrong direction or the headlights don’t work then the decoder is plugged in the wrong way round; unplug the decoder, turn the plug through 180º, replace it and then go back to step 4, above. Yep - I got it the wrong way round...

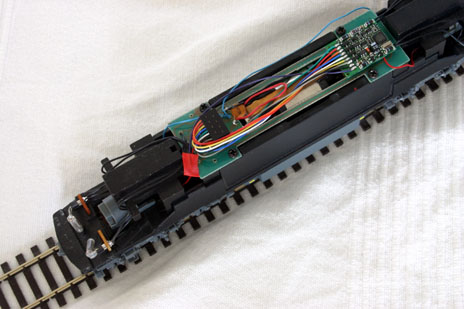

- Permanently install the decoder; insulate any unconnected wires, sticky pad (or otherwise retain) the decoder into its location and replace the loco body.

- Return the loco to the programming track and hard reset the decoder. This tends to involve putting a certain value (identified in the decoder manual) into CV8 – but it may use another method so it’s worth checking the decoder manual and following their instructions explicitly. This stage is often missed out in installation guides, but it will help wipe the memory of the decoder if the manufacturer has used the decoder for testing, or if you’ve inadvertently static-charged the decoder during the installation.

- Carry out any specific programming you want. Change the Address, take account of motor type/operation, alter the top speed, smooth the acceleration, change the light settings etc…!

Of course if your loco isn’t ‘DCC ready’ then it won’t have a socket. The first thing to do is to make sure that the motor can be completely isolated from the chassis. If it can’t, you’ll zap the decoder as soon as you put it on the track. This can sometimes call for a creative solution or two, especially with older models, but; real troublemakers can still be converted with care – I’ve even managed to DCC-ise a couple of Brawa Kof2 diesel shunters. You can make a socket to take a decoder which can be useful for some models, or you could use a ready-made socket from the likes of ESU, or you can hardwire. The decoder instructions will provide you with a schematic diagram for hardwiring but here’s a quick précis of the standard wiring colours:

- Red – Right hand track contact

- Black – Left hand track contact

- Orange – Right hand motor contact

- Grey – Left hand motor contact

- White – Function output A (Front headlight, f0)

- Yellow – Function output B (Rear headlight, f0)

- Blue – Function positive common

- Green – Function output C (normally controlled by f1)

- Purple – Function output D (normally controlled by f2)

The Green and Purple wires for functions outputs C and D are only going to be found on a 4-function decoder. On sound decoders the f1 and f2 buttons are normally used for controlling sound functions, f1 being on/off and f2 whistle, so the Green and Purple function wires may not be present.

Recommended decoders

We've now spent quite a time evaluating decoders and now found a few we like; there were some (even popular ones) we didn’t like. But in the positive spirit of the website we’ll not ‘name and shame’, just offer plaudits for those we now feel comfortable recommending. I should mention that we've no personal or professional connections with any of the distributors or manufacturers of these items; we're simply users of these products. With the caveat out of the way I guess it's time to present the list...

ESU LokPilot v3.0

This type has very impressive specifications and very good performance. It's also safe and simple to set up. Of course, with ESU there’s also the chance to use sound, the LokSound v3.5 uses the same drive technology as the LokPilot v3.0…

Lenz LE1024, LE1025

A basic, and now elderly, decoder family. They are all but identical in their performance and functionality, one is single sided (LE1024)and the other double sided (LE1025). With careful programming of the speed curve and motor control CVs, particularly with respect to the minimum speed and drive frequency (there’s something of a trade-off) the performance with conventional can motors can be exemplary. Not the quietest decoder we’ve ever used though as it’s not got Lenz’ ‘silent drive’ feature.

Lenz ‘Gold’, ‘Gold Mini’

The current top spec Lenz decoder family. Both the standard ‘Gold’ and N-gauge ‘Gold Mini’ are very good; we’ve not tried the ‘Gold Maxi’ large-scale decoder but I wouldn’t have any major worries about doing so. This is a very impressive piece of kit supporting a lot of the advanced DCC features, motor configuration, etc, etc. The drive technology is especially impressive and the decoders can be used with Lenz ‘Power 1’ modules providing an on-board power source to carry the loco over dead or dirty track. Although there are 5 pre-set motor drive functions, in most cases they’re actually superfluous (did I really say that?), I normally run them on the factory settings. These decoders (unusually) are equally good driving r-t-r or kit-built locos as long as decent can motors are employed; I haven’t tried using one with a coreless motor and wouldn't recommend it even though I’m told it’s feasible. The HO and large-scale versions of these decoders are fitted with SUSI connections if you need higher functionality such as an external sound decoder…

Lenz ‘Silver’

Much as the ‘Gold’ really; only cheaper, with fewer advanced functions and no SUSI or ‘Power 1’ provision. Uses identical motor control system so it’s a pretty handy piece of kit.

Zimo MX61 2000

My first contact with Zimo was fitting a couple of these decoders into American brass locos with Canon coreless motors. I’d been searching for suitable decoders for ages so I bought these (£40-ish at the time so hardly cheap) primarily out of desperation. I was suitably impressed and still rate these as the best decoder for coreless motors operating under ideal conditions. The starting torque is a bit limited (maybe indicating a reduced current drive at low voltage?) so they need very smooth running locos. There are loads of CVs for adjusting motor performance so you can get superb performance out of this decoder. This decoder is now obsolete.

Zimo MX62

Zimo’s N-gauge decoder. This is a lovely unit, very useful in terms of size, power and capabilities. It comes in two versions; the early ones have black epoxy covering most of one side, the later ones don’t so can be attached to an on-board power source. This is a good decoder for coreless motors, particularly in small locos. The six pin ‘direct’ version is useful for the majority of DCC-ready Fleischmann locos (why do Fleischmann insist on using an N-gauge 6-pin decoder socket in their HO locos – aaagh!) and the MX62s current limit is high enough to cope in most cases. Recently superseded by the MX620.

Zimo MX620

Zimo have updated the MX62 with a new version, the MX620. This takes the MX620 and develops it further with a few more CV options including a custom drive setting for coreless motors. As we have a number of smaller locos powered by coreless motors this was always going to be an intriguing possibility. And, as you'd expect it works very well with conventional motors too.

Zimo MX63

The current high-end from Zimo. Still not hugely expensive and with the capability to run very well with coreless (or indeed any other type of) motors thanks to full drive CVs. This decoder also has SUSI connections and can use on-board power.

Zimo MX64

A somewhat cheaper, single sided version of the MX63. Subjectively this decoder isn’t quite as smooth or quiet as the MX63, but on paper supports identical functionality; including SUSI and on-board power.This is the best decoder I’ve found that works smoothly, quietly and reliably with Liliput locos (particularly the later, Chinese-built stuff)

A few favourite decoders in depth

ESU LokPilot v3.0

The LokPilot v3.0 is a new decoder to us, but it's very useful for a wide variety of loco types...

Lenz Gold (+ Power1) and Silver

This family of decoders have a couple of neat tricks up their sleeves, including the ability to connect Lenz proprietary Power1 energy store.

Zimo MX series

Probably the most adaptable and advanced locomotive decoders in the business.